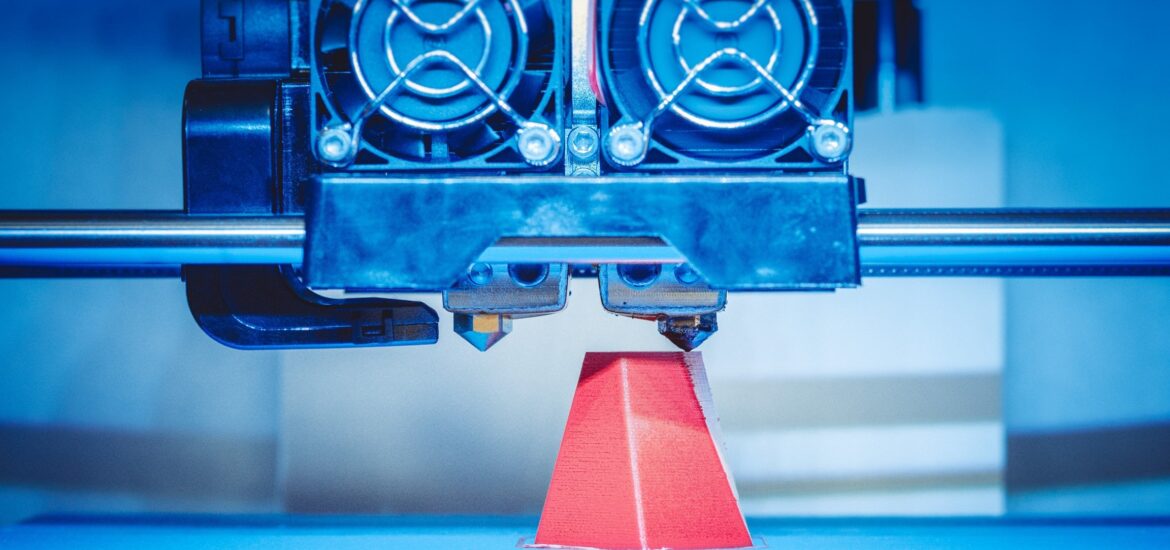

Industrial manufacturing is undergoing a rapid transformation and the pandemic accelerated the pace of change. Digital technologies and changing customer demands are revolutionising the manufacturing landscape and how value is created, dramatically increasing the overall level of uncertainty. Still, there are many opportunities to drive growth. Industrial manufacturing 4.0 — or the manufacturing for the digital age — is based on digital technology and novel methods such as big data and analytics, smart interconnected devices and cloud computing, advanced robotics and automated machines as well as additive manufacturing (3D printing) and advanced materials.

Big data analytics

Modern manufacturing is a data-rich environment that supports the collection, transmission, sharing, and information analysis across the organisation to produce invaluable intelligence. The global big data analytics in the manufacturing industry was valued at USD 904.65 million in 2019 and is expected to reach USD 4.55 billion by 2025, growing at a CAGR of 30.9% from 2020 to 2025. Like most organisations, industrial manufacturers are creating a growing digital footprint and have access to operational and business data from their processes, assets and workflows. They can leverage this vast amount of data about their inventories, products, people, and finances to gain a competitive advantage, control costs, optimise the use of resources and manage sustainability efforts amid evolving regulations. Big data analytics enable manufacturers to optimise manufacturing and field operations and respond to key business needs by integrating the data from and into the products themselves. Big data fuels other novel technologies such as the Internet of Things, robotics and automation and AI. Intel cites automation and the effective use of data as core elements of its competitive strategy.

Industrial Internet of Things

Internet of Things refers to the network of interconnected devices that communicate via embedded sensors and wireless networks. It is revolutionising the businesses across the board. Data-gathering and analytics capabilities enabled by the interconnected devices offer a new source of value across the whole of the supply chain and manufacturing processes, opening new possibilities never seen before. IoT allows operational technology and information technology to join forces to transform manufacturing and empower organisations to create new ways to optimise operations and engage with customers.Click here to learn more.